| ||||

|---|---|---|---|---|

|

|

|

|

|

| ||||

|---|---|---|---|---|

|

|

|

|

|

Allgemeine Elektricitäts-Gesellschaft (A.E.G.) G.IV Bomber

German, World War I Twin-engine Biplane Bombers

.jpg)

Archive Photos 2,3

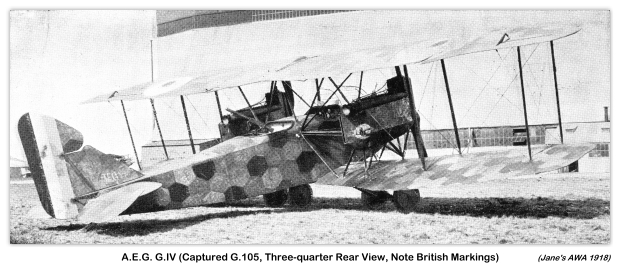

Allgemeine Elektricitäts-Gesellschaft (A.E.G.) G.IV (A.E.G. G.IV s/n G.105 shot down by British anti-aircraft fire on 23 December 1917. Note the British markings on the aircraft, Photos from Jane’s All The World’s Aircraft 1918, pgs 195b-198b) 2

![(A.E.G. G.IV Front View of Captured G.IV, s/n G.105. Note the British Markings. (Photo from <i>Jane’s All The World’s Aircraft 1918, pg. 195b) [2]](https://www.skytamer.com/archive-thumbs/A/AEG/250/A.E.G. G.IV Front View.jpg)

![(A.E.G. G.IV Three-quarter Front View of Captured G.IV, s/n G.105. Note the British Markings. (Photo from <i>Jane’s All The World’s Aircraft 1918, pg. 1956) [2]](https://www.skytamer.com/archive-thumbs/A/AEG/250/A.E.G. G.IV Three-quarter Front View.jpg)

![A.E.G. Three-quarter Rear View of Captured G.IV, s/n G.105. Note the British Markings. (Photo from <i>Jane’s All The World’s Aircraft 1918, pg. 197b) [2]](https://www.skytamer.com/archive-thumbs/A/AEG/250/A.E.G. Three-quarter Rear View.jpg)

![A.E.G. Side View of Captured G.IV, s/n G.105. Note the British Markings. (Photo from <i>Jane’s All The World’s Aircraft 1918, pg. 198b) [2]](https://www.skytamer.com/archive-thumbs/A/AEG/250/A.E.G G.IV Side View.jpg)

Allgemeine Elektricitäts-Gesellschaft (A.E.G.) G.IV (German AF 574-18) at the Canada Aviation Museum, Ottawa, Ontario, Canada (9/17/2003 photos by John Shupek,) 3

G.IV Bomber 20030917-130.jpg)

G.IV Bomber 20030917-131.jpg)

G.IV Bomber 20030917-132.jpg)

G.IV Bomber 20030917-133.jpg)

G.IV Bomber 20030917-134.jpg)

G.IV Bomber 20030917-135.jpg)

G.IV Bomber 20030917-136.jpg)

Overview 4

The AEG G.IV was a biplane bomber aircraft used in the World War I by Germany. It was developed from the AEG G.III, with refinements to power, bomb-load, and dimensions. Serving late in the war, the AEG G.IV managed to achieve some operational success in reconnaissance and combat roles. Coming into service in late 1916, it featured a bomb capacity twice as large as that of the AEG G.II, but was still considered inadequate in terms of offensive capacity and performance. Further improvements led to the development of the AEG G.V, but the Armistice came before the replacement could become operational.

Design and Development 4

The Allgemeine Elektricitäts-Gesellschaft (A.E.G.) G.IV was derived from the earlier AEG G.III. Designed as a tactical bomber, the relatively modern technology included onboard radios and electrically heated suits for the crew. The AEG G.IV also had a quality that endeared it to the men who flew it - it was an extremely rugged aircraft. Unlike the other German bombers such as the Gotha and the Friedrichshafen, the AEG featured an all metal, welded tube frame. Well equipped with armament, although the rear gunner’s cockpit was on the top of the fuselage, the position was equipped with a hinged window in the floor for viewing and fending off pursuing aircraft.

Operational History 4

The AEG G.IV bomber entered service with the German Air Force in late 1916. Because of its relatively short range, the G.IV served mainly as a tactical bomber, operating close to the front lines. The G.IV flew both day and night operations in France, Romania, Greece and Italy, but, as the war progressed, the AEG G.IV was restricted increasingly to night missions. Many night operations were considered nuisance raids with no specific targets, but with the intention of disrupting enemy activity at night and perhaps doing some collateral damage.

The AEG G.IV carried a warload of 400 kg (882 lb). While Gotha crews struggled to keep their heavy aircraft aloft, the AEG was renowned as an easy machine to fly. Some G.IV crews of Kampfgeschwader 4 are known to have flown up to seven combat missions a night on the Italian front. A notable mission involved Hauptmann Hermann Kohl attacking the railroad sheds in Padua, Italy in his AEG G.IV bomber.

A single example is preserved at the Canada Aviation Museum. This example is significant not only as the only one of its kind in existence, but as the only preserved German, Twin-engine combat aircraft from World War I.

Variants 4

Operators 4

Specifications and Performance Data (AEG G.IV) [2,5]

Report on A.E.G. Bomber, G.105 7

This machine was brought down by anti-aircraft fire at Achiet-le-Grand on 23 December 1917.

On a label protected by celluloid, mounted on a tube in the nacelle, is the legend — Abnahme am (Accepted on) 10/11/17. (11 October 1917)

This machine, whilst carrying a similar power plant, is very different in construction from the Gotha type, which also embraces the Friedrichshafen Bomber reported on in I.C. 619.

Whereas the latter is generally constructed of wood, ply wood being used to a very large extent throughout, in the A.E.G. steel is almost universally employed, not only in regard to the fuselage, nacelle, subsidiary surfaces and landing gear, but also in the wings themselves.

Needless to say, acetylene welding is freely resorted to throughout the construction, which, however, appears to be far from light.

On the whole, the A.E.G. aeroplane, judged by contemporary British standards of design, is decidedly clumsy, not only in detail work, but also in appearance. The performance is poor.

The leading particulars of the machine are as follows:

- Wing span: 60 ft. 4¼ in. (18.4 m) 5

- Length: 31 ft. 10 in. (9.7 m) 5

- Weight empty: 5,258 lbs.

- Total weight: 7,130 lbs.

- Area of upper wings: 395.2 sq. ft.

- Area of lower wings: 335.2 sq. ft.

- Total area of wings: 730.4 sq. ft.

- Loading per square foot of wing surface: 9.77 lbs. per sq. ft.

- Area of ailerons, each: 17.9 sq. ft.

- Area of balance of aileron: 1.8 sq. ft.

- Area of tail plane: 34.0 sq. ft.

- Area of fin: 11.5 sq. ft.

- Area of rudder: 20.8 sq. ft.

- Balanced area of rudder: 2.6 sq. ft.

- Area of elevators: 31.2 sq. ft.

- Balanced area of elevators: 3.6 sq. ft.

- Horizontal area of body: 206.4 sq. ft.

- Vertical area of body: 209.2 sq. ft.

- Total weight per horse power: 13.7 lbs. approx.

- Crew-pilot and two passengers: 540 lbs.

- Armament: 2 guns.

- Engines: 2 × 260 h.p. Mercédès.

- Petrol capacity: 123 gallons = 861 lbs.

- Oil capacity: 11 gallons = 110 lbs.

- Water capacity: 13 gallons = 130 lbs.

- Other dimensions are also shown on the drawings at the end of the Report.

Performance

- Climb to 5,000 ft: 10.3 minutes.

- Rate of climb at 5,000 ft.: 390 ft/min.

- Climb to 9,000 ft.:23.4 minutes.

- Rate of climb at 9,000 ft.: 235 ft/min.

- Level speed to 5,000 ft.: 90 mph approximately.

- Level speed at 9,000 ft.: 86 mph approximately.

- Landing speed: The airplane is best landed at a speed between 75 and 80 mph; after flattening out it sinks to the ground quickly and pulls up rapidly.

- Control, lateral: Good.

- Control, elevators: bad, especially when landing.

- Note: Is is stated that is not advisable to fly this machine without a passenger in the front seat.

Construction

The wings are of characteristic form. The central portion consists of a rectangular center cell permanently attached to the fuselage. The lower wings support the engines. In this center cell the planes are set horizontally. At each side of it the lower main planes are swept upwards with a vertical dihedral of 2.75°, the top planes being kept flat, and both main planes are swept backwards in the horizontal plane to an angle of 4° for the bottom plane and 3° for the top plane. As the central portion of the upper main plane has 4 inches of negative stagger relative to the bottom plane, this difference in angle brings their tips practically vertically over one another. The angle of incidence attains a maximum of 4° at the base of the engine struts, i.e., 7 ft. 10⅜° inches from the center. At the second strut the angle is 3½° and at the end strut 2½°. These angles are painted in circles on the surface of the planes, evidently for the convenience of riggers. The camber of both planes is washed out gradually towards the tips.

The main spars are kept parallel throughout the whole of their length and are attached to the central cell by means of pin joints, similar to those on the Friedrichshafen. The ribs are of solid wood. It is rather notable in comparison with other German machines of all types that ply wood is almost entirely absent. In the A.E.G. construction the rib webs are perforated and strengthened by wooden uprights at intervals and are glued into a grooved flange. The ribs are placed 300 mms. - 325 mms. apart — and are not directly or firmly attached to the spars on which they are a relatively loose fit. Passing through the ribs of the bottom plane and extending from their junction with the center section to the extreme outside strut are two steel tubes, approximately 17 mms. in diameter, which act as housings for the aileron control wires. These tubes are very strong, and it is thought possible that they are also counted upon to lend rigidity to the wing structure.

The leading edge, which is of the usual semi-circular section, acts as a distance piece, as also does the wire trailing edge. Thirteen inches in front of the last-named is a stringer formed of a steel rod. Apart from this, the spars are the only longitudinal members of the wings. Between the main ribs are false ribs running from the leading edge to a point a few inches behind the leading spar and applying only to the upper surface.

The lower plane is covered as to its upper surface with sheet metal immediately under the engines, whilst between them and the fuselage is fixed a strip of corrugated aluminum which acts as a footway. The fabric is attached in the usual manner and is stitched to the ribs both top and bottom. The two surfaces are stitched together behind the metal rod which acts as a stringer, and by this means the actual trailing edge wire is relieved of a certain amount of tension. The wing structure is internally braced by means of steel tubular cross-pieces and stranded cables. A single fitting is employed for the attachment of the interplane struts and for that of the bracing tubes. It is a tight fit on the spar, to which it is fixed by a bolt, and is formed with an extension lug which acts as an anchorage for the bracing tube, whilst a sideways extension of the same lug carries an eye for the bracing wire. It is provided with a cup-shaped upper extension, into which there is screwed a steel dome which carries the ball of the strut socket fitting and also acts as a wiring plate for the interplane bracing wires.

The fabric is run into the space between the upper and lower flanges of this fitting, the whole making a very neat job.

Struts

These are of streamline section steel tube and of uniform dimensions throughout. The section is 92 mms. long by 48 mms. broad. The ends are sharply tapered down, and into them is welded a cupped ferrule which drops onto a ball, and is there held in position by a cotter-pin. This joint gives a considerable range of lateral freedom, as is the usual practice on machines of German design.

Fuselage

The whole of the fuselage is built up of steel tubes welded together. It is of plain rectangular section and the cross tubes are attached directly to the main booms without the intervention of any clips.

Under the nacelle, and in the neighborhood of the main petrol tanks and the bomb racks, the fuselage is reinforced with thin tubular steel tie-rods.

The upper booms of the fuselage are provided with sockets for the inclined struts of the central cell. The fitting consists of two circular steel plates welded into position to form an integral part of the frame joint, the front one of these flanges being provided with lugs for the anchorage of bracing cables. The inclined struts are secured by a ring of short set screws wired together as shown. If appearances are to be trusted, this form of attachment, whilst being strong and convenient, is excessively heavy. Unlike the practice which is pursued in the Friedrichshafen Bomber, wherein the main frame consists of three separate sections, that of the A.E.G. is in one piece from stem to stern. The longerons are 30 mms. in diameter and the transverse members 30 mms., these dimensions being retained up to the extreme tail end. The nose part of the frame is covered in with three-ply wood, but behind this a double covering of fabric is used, under which the tubular construction is completely hidden. Behind the after cockpit a single covering only is adopted and laced the whole of its length so that it is removable in its entirety.

Engine Struts

These are of streamline steel tubing and embrace joints of a somewhat similar type to those used on the interplane struts: that is to say, a certain amount of free movement is provided. The mounting of the engines is clearly shown in the front and side elevations. In front there are four struts which converge to a joint on the leading spar, whilst at the rear there are two struts which meet at a joint on the trailing spar.

The bell-shaped housing attached to a cup on the spar joint contains a ball-ended set screw which screws into the foot of the four struts which are here united by welding. The inclined transverse struts are taken from the spars to the engine mounting and cross struts from thence again to the upper booms of the fuselage. In order to provide simplicity of erection these subsidiary struts are provided with a means of adjustment. At one end they terminate in a ball-ended set screw screwed into the tapered end of the strut and secured by a lock-nut.

Engine Mounting

The engine bearers are of steel rectangular section, measuring 40 mms. high by 30 mms. broad, with a wall thickness of approximately 2 mms. These bearers are welded to the struts which support them, and for the greater part of their length are reinforced by a system of tubular tie-rods also welded in position. Box attachments welded to the engine bearers, are provided for the crank chamber holding-down bolts. The engine is not directly mounted on the steel bearers, but upon ½-inch wooden washers. Owing to the deformation inseparable from so much welding, the engine mounting is of very clumsy appearance, and, in fact, the quality of welding does not appear to be up to previous German standards, but the construction would appear to be light.

Engine Fairing

As shown in the photographs, the engines are almost completely enclosed in a fairing composed of detachable aluminum panels. The necessary framework and clips are provided for panels totally enclosing the engine, but it would seem that this bonnet right over the heads of the cylinders has been discarded. The tubular framework which supports the panels is an elaborate piece of work comprising a multiplicity of welded joints. It consists of 16 mm. tubes, to which are attached lugs for carrying the necessary turn-buttons. The framework is made in two halves so as to be easily detachable, and a joint for that purpose is made. It will be noticed that a narrow slot for the exit of air passing over the engine is provided at the rear end of the engine egg, an opening of somewhat similar dimensions being between the two halves of the radiator.

Engines

The engines are the standard 6-cylinder 260-h.p. Mercédès. [These engines are fully described, in the Engine Section and no important novel points are adopted.] A new shape has been adopted for the exhaust pipe, and this is clearly shown in one of the photographs - an inverted cone is placed in the belled mouth of the pipe. The usual water-pump greaser is fitted and worked by a lever in the pilot’s cockpit. It is of rather less clumsy design than that of the Friedrichahafen, but employs the same principle. The throttle is interconnected with the ignition advance.

A small fitting, the purpose of which is not clear, is fixed to the carburetor, and consists of a bell-shaped cover over the top of the float chamber, not directly connected thereto, but supported on a bracket clipped to the main water pipe. The bell is free to slide up and down the stem of the bracket, on which it is a very loose fit, but is prevented from falling over the float chamber by a small washer. It is conjectured that this fitting may have for its purpose the prevention of petrol having access to the hot exhaust pipe in the event of the machine turning over. Between the bell and the float chamber is a clearance of about ¼-inch.

Petrol System

There are two main tanks, each of 270 liters = 95 gallons total capacity, and these are placed under the pilot’s seat in the main cockpit. Two subsidiary tanks, used solely for starting purposes and giving a gravity supply, are mounted in the center section of the top main plane and are of roughly streamline form. Beneath them is a small cowling containing their level gauges, which are visible from the pilot’s seat.

On the right hand side of the main cockpit is fitted a hand-operated wing pump, the object of which is to draw petrol from either of the main tanks and direct it to the gravity tanks. Pipes from all four tanks are taken to a distributing manifold on the dashboard, and by means of seven taps thereon the supply of petrol can be directed from any one of the tanks to either engine or both. Two additional taps are provided on the wing pump so that the fuel for the gravity supply can be drawn from either main tank as required. It would appear that most of the various troubles associated with this form of tap have been overcome, as they show no signs of leaking or sticking. The level of the main tanks is indicated on the dashboard by two Maximall gauges. Those attached to the gravity tanks are made by Laufer and employ the static head principle. They read up to 45 liters each, from zero to this figure being given by one and a half complete revolutions of the indicating hand.

Petrol Pressure System

The usual pressure pump is mounted on each engine and pipes there from are led to a manifold mounted on the dashboard. This is also connected to a large hand pump on the right hand side of the pilot’s seat. Gauges reading the pressure from each engine pump are provided, and there is also a blow-off tap for relieving the pressure of tho whole system.

Oil System

This is the usual system as fitted to all 260-h.p. Mercédès engines. The main supply of oil is carried in the crank-chamber sump and is continually being refreshed by a small additional supply of fresh oil drawn from an external tank. This tank has a capacity of 5 gallons, is of rectangular shape, and is mounted at the side of the engine nearest to the fuselage. It is provided with a visible glass level over which is a celluloid covered window let into the engine fairing, so that the oil level is visible from the pilot’s seat.

Radiator

Each radiator is composed of two halves bolted together. The space between the two halves is partially covered with a sheet metal panel pierced with a hole 1 ft. 6 in. high by 4 in. wide. The radiator is not actually honeycomb, though presenting that appearance. It consists of a series of vertical tubes with transverse gills. Each radiator cell measures 2 ft. 3¼ in. high by 7½ in. wide, and has a uniform depth of 4 in. Each complete radiator is provided with two shutters of roughly streamline section. These, when fully closed, cover over about one-third of the radiating surface.

They are controlled from the pilot’s seat by two levers which work them through universally jointed rods.

Engine Control

The throttle levers are of the plain twin variety. They are placed close together so as to be easily worked either in unison or separately. The connections between the levers and the carburetor are made as simple as possible, and the levers operate the throttle through a couple of universally jointed rods which extend from each side of the body to the engine eggs.

Tail Planes

The fixed horizontal tail planes are notable for their extremely bold curvature, both top and bottom. The framework consists entirely of welded steel tubing. The leading edge of the tail plane is mounted so as to be adjustable in case of necessity, a simple bracket being used for this purpose. This is welded on to the fuselage upright at each side and strengthened with a transverse stay. It allows the tail plane leading edge to be fixed in one of three positions. The trailing edge of the tail plane is supported each side by a streamline section steel tubular strut.

Fin

The fin, like the fixed tail plane, has also a very strongly marked streamline section at the base, tapering off to flat at the top, where it abuts against the balanced portion of the rudder. At this point its framework, which is of light steel tube, is made rigid by a couple of tubular stays bracing the rudder post to the sides of the fuselage.

Rudder and Elevators

These organs are built up of steel tubular framework and present no points of special interest, except that in the case of the rudder that part which is above the fixed fin is made of grooved section.

Ailerons

As may be seen from the plan view of the complete machine, the shape of the ailerons is somewhat unusual. These are applied to the top plane only and have a chord which reaches its maximum at their extreme ends and its minimum in the center of their length. For what purpose this peculiar shape is adopted is not clear. The framework of these ailerons is welded steel tubing, and the control crank is fitted in such a way as to lie partially hidden in a slot in the main plane. This crank is built up of welded sheet steel, an elliptical hole being cut in the trailing edge of the main plane for the passage of the forward wire.

Control

The main control consists of a wheel mounted on a pivoted lever, the wheel operating the ailerons by means of a drum and cables, which pass direct over pulleys and along tubes running parallel with the wing spars and then over inclined pulleys up to aileron cranks. The wheel column is pivoted to a long crossbar extending the whole length of the fuselage and carrying at each end cranks for the elevator control wires which at intervals are carried through fiber-guides socketed to the frame. The cranks of the elevators are concealed inside the rear end of the fuselage, whilst those of the rudder (which is fitted with duplicate cranks and wires) are external. A modified dual control is fitted, which allows the assistant pilot to work the elevator and rudder only. For this purpose, a socket is mounted on the pivot bar into which can be inserted a plain steel tube, which is normally carried in clips behind the pilot’s back. A second rudder bar is carried under the dashboard, and can readily be dropped into position into a square socket partially sunk into the floor of the cockpit and connected to the pilot’s rudder bar by cranks and a link.

Personnel

Seats are provided for a crew of four, who are carried as follows:

- One in the front cockpit.

- One in the pilot’s seat.

- One at the pilot’s side.

- One in the rear cockpit.

All can, if necessary, change places whilst the machine is in the air. Between the front cockpit and that of the pilot a sliding panel is provided through which the gunner can crawl. The seat at the side of the pilot folds up and slides back into a cavity under the coaming of the nacelle and when in this position allows access down a narrow and inclined passage-way to the rear cockpit. The machine can hardly have been designed to satisfy the requirements of the average pilot in regard to view, as from the pilot’s seat it is very difficult to see the ground properly, on account of the position of the lower main plane and the width of the fuselage.

Armament

Two Parabellum guns are mounted, one in the front cockpit and one in the rear, and provision is made for mounting a third or for transferring one of the others on the floor of the rear cockpit, so that it can fire backwards and under the tail of the machine. For this purpose, a large trap door is provided in the floor of the fuselage, behind the rear cockpit. This trap door has celluloid windows and is normally kept closed by springs. It is lifted up by a small hand winch fitted with a ratchet. It is of passing interest to note that whereas in the Friedrichshafen a similar trap door was kept open by means of springs, in the A.E.G. springs are used to keep the door closed. In the front cockpit the gun is supported on a carriage which runs round a partially circular rail which is strongly supported from tho fuselage by a framework of steel tubes Forming part of this frame is an inclined steel tubular column, the base of which is fitted in a swivel bearing in the floor of the cockpit, and on this is mounted an adjustable seat for the gunner. A toothed rack runs round the rail and engages with a spur pinion driven by a hand wheel so that the gunner, when occupying his seat, swivels himself round as well as the gun. The vertical swivel of the fork-ended gun carrier is locked by a ball-ended lever and a similar lever is employed for locking the carriage itself to its rail.

This action is accomplished by a cam device which depresses the roller of the carriage and squeezes the rail section between the roller and an adjustable set screw which normally just clears the groove on the under side of the rail. In order to prevent the forward gunner from shooting the tractor screws, preventative shields of light steel tube are carried between the upper edge of the forward cockpit and the inclined struts of the center section. These impose a limit to the travel of the gun. In the rear cockpit the gun mounting is U-shaped in plan form, and here again the principle of a carriage running on a rail and driven by a spur gear meshing with a toothed rack is employed, though in this case the gunner’s seat does not revolve with the gun. The carriage is of a somewhat similar type to that used in the front cockpit, but the method of locking it is different. The rail is provided with grooves both above and below, there being two rollers at the top and one underneath. Normally, when the gun carriage is free, the latter is clear of the rail, but when tho locking mechanism is brought into action it is forced upwards so that the rail is gripped between the rollers, thus avoiding any possibility of shake at this point, and at the same time a positive lock is obtained on a second rail carried below the first. When the ball-ended hand lever is tightened, its effect is to squeeze the lower rail between two jaws. The movable jaw is, however, connected up by a link to a small cam, the base of which abuts against the foot of a fork-ended rod which carries the lower roller and is free to move up and down in a guide, to the base of which the cam is pivoted. By this means a very secure and rapid locking device is obtained. In the front of the rear cockpit, a locker is provided which would be capable of holding ammunition, and beneath this a series of racks.

Bombing Gear

Three racks for holding twenty-five pounder bombs are installed on the machine; two side-by-side on the left side of the rear cockpit, and one on the right side of the petrol tanks in the space between the pilot’s and rear cockpits. This rack is covered by a detachable wooden lid which acts as the floor of the narrow gangway mentioned above. Underneath the center of the nacelle, provision is made for carrying two or more large bomb racks, which, however, were not in use on this machine. Underneath the lower main plane, two at each side of the nacelle, are fixed bomb clips which are capable of supporting bombs roughly 8 inches in diameter. They are held in position by a belly-band consisting of two steel strips. Eleven-and-a-half inches in front of this clip is a bracket suitable for a circular section of 4 inches in diameter, and 13½ inches in the rear of the clip is a second bracket suitable for a 5 inches diameter section. The bomb would thus appear to be 50 kilograms. At their fixed end they are supported on a crosshead. This in turn is carried on a bracket clipped to a steel tube running parallel to the wing spars and braced thereto by tubular steel girders. The crosshead is free to swivel on the bracket against the action of a coiled spring, which, when the bomb has been released, twists the crosshead round against a stop, so that the belly-band is forcibly swung round and now faces the direction of flight, instead of lying edgewise on to it. The ends of the steel strips are swivelled on the crosshead, and here again coil springs are used, so that the tendency is for the belly-band to be held flat against the lower surface of the bottom main plane, and out of the way of the other clip.

When the bombs are in position, the rings which are fitted on the free end of the belly-band are caught between the jaws of a trigger mechanism. This device is carried on the same tube which supports the crossheads, as already mentioned. Lying parallel to this tube and between it and the leading spar is a control rod fitted with two levers which are connected respectively to the two bomb trip gears, and this rod is operated by a quadrant lever mounted in the front cockpit. In order to allow one trip gear to be worked at a time, the link of the outer trip is provided with a slot where it is pivoted to the trigger release. On working the lever in the cockpit, therefore, its first action up to half way over the quadrant is to release the bomb nearest the nacelle, whilst a further movement releases the outer bomb.

An exactly similar method is employed for operating the bombs carried underneath the other wing. The levers in the front cockpit are all mounted on a common bracket built up of steel tubes, and are arranged as follows: First, there are the two levers which control the two bomb magazines in the rear cockpit. These are provided with thimbles and chains, so that they cannot be operated accidentally. Next a single lever, which controls the larger bomb clips on the right wing. These are capable of being secured by split pins inserted in their quadrants. Next, there is a lever which in this particular machine was furnished with no action at all, but is evidently designed for manipulating the large bomb carriers when these are installed. Behind it are, first, a single lever for the left hand outer bomb clips, and, finally, the lever for working the bomb magazine on the right hand side of the nacelle.

Landing Gear

The landing gear of the A.E.G. bomber is simply an elaboration of that which has become practically a standard fitting on single and two-seaters, except that in this machine the gear is in duplicate. It consists of two axles carrying two wheels a-piece, and suspended from pairs of V struts. One pair is connected to the spars of the center section immediately underneath the engine strut sockets, and the other to the spars midway between this point and the fuselage and at the same point from which diagonal struts are taken from the spars to the engine mounting and nacelle. This, together with the wire bracing of the landing gear struts, provides a completely triangulated construction. The struts are, however, connected by ball joints similar to those used with the engine struts, so that in case of strain a certain amount of free movement can take place. The pairs of V struts carry at their foot a hollow steel crossbar having the section of a trough, and in this lies the axle which connects the two wheels.

The fixed beam has forward and rearward extensions, at each end of which are anchored the ends of the batteries of coil springs which act as shock absorbers, and at their other ends are hooked to a horn plate on the wheel axle. Each battery of springs, of which there are four to each axle, consists of 18 springs. A yoke of stranded steel cable restricts the movement of the axle beyond a certain limit. The tires are 32 in.. × 6 in.. = 810 × 150. A tail skid of massive proportions is used.

Wireless

The machine is internally wired for wireless, and a special dynamo for supplying current for this purpose and also for heating is installed on the right hand engine. This dynamo bears the following inscription:

Telefunken

- J. P. Flieg. C 1916. Type D.

- Alternating current 270 Watts. 5 amperes. 600 frequency.

- Continuous current 50 volts. 4 amperes. r.p.m. 5,400.

The dynamo is mounted on brackets acetylene-welded to the steel engine bearers, and is normally completely enclosed in a detachable fairing. The dynamo drive embraces the pulley, which is a standard fitting on the 260-h.p. Mercédès, but in this particular case the clutch gear whereby the driving pulley can be disconnected from the engine as required, appears to have been discarded. Two sets of wires are taken from the dynamo inside flexible metal conduits to a pair of plugs situated at the junction of the fuselage and the right hand lower main plane. Here they terminate in plug sockets, so designed that the plugs cannot be inserted wrongly. One of these wiring circuits apples to the heating system, and wires for this purpose are carried to points in all three cockpits, whilst the other circuit is for wireless and terminates in a plug adaptor in the rear cockpit. No wireless instruments were fitted. Two plug sockets for the pilot’s cockpit and one for the forward gunner. A small plate on the pilot’s dashboard carries the following inscription, but no definite information is given:

- F. T. Fitting. W/T Set.

- Aeroplanes.

- Type 94. NY&mbsp;1125/16.

- Fitting, No. 85a.

- Driving propeller. Type. Direct coupling.

- Length of aerial wires — — — —

- Telefunken transmitter — — — meters.

- Huth transmitter. — — — — meters.

- D transmitter. — — — meters.

- G transmitter. — — — meters.

In addition to these two circuits, there is a lighting installation in conjunction with a battery carried in a box in the rear cockpit. From here, wires are taken to each cockpit and also to the tail and via the leading edge of the upper plane to the extreme outside strut of each wing. On these struts red and green lights are carried. Inspection lights are provided at convenient points in each cockpit over the dashboard, instruments, etc.

For the most part the lighting wiring is contained inside a light celluloid conduit.

Instruments

These comprise twin engine revolution counters, twin air pressure gauges for the petrol supply, electric thermometer, altimeter, petrol level gauges, etc. All of these are of recognized types and call for no detailed description.

Camouflage

This machine is camouflaged in six different, colors on a uniform system covering every portion. The colors are arranged in hexagons measuring roughly 18 in. across the flats, and the colors are sage green, reddish mauve, bluish mauve, black, blue and grey. These colors are not flat washes, but are softened by being stippled and splashed with paint of a lighter tone. Considerable care appears to have been taken with this camouflage scheme, which is presumably effective.

Fabric and Dope

The fabric throughout is of good quality and the dope acetate of cellulose.

Airscrew

- Diameter 10 ft. 3.8 in. + 0.20 in.

- Pitch 59.3 in.

The following table gives the thicknesses of the various laminæ used in construction of the airscrew. The laminæ are numbered from the trailing to the leading edge.

No. Material Thickness in inches 1 Walnut 0.73 2 Mahogany 0.80 3 Mahogany 0.80 4 Mahogany 0.80 5* Mahogany 0.80 6 Mahogany 0.80 7* Mahogany 0.40 8* Mahogany 0.40 9 Mahogany 0.80 10 Walnut 0.83 * These laminations were of a quite different kind of mahogany, probably African. Only one airscrew has been seen and dimensioned. Thus it is unknown whether all airscrews would have laminæ of similar thicknesses and of similar timbers. There is no apparent reason why these laminæ should be of different thicknesses. It is surmised that either the enemy is short of timber or that he has a highly scientific reason for so doing that we do not know. The port and starboard airscrew rotate in opposite directions.

W. G. A.,

March, 1918.

References