| ||||

|---|---|---|---|---|

|

|

|

|

|

| ||||

|---|---|---|---|---|

|

|

|

|

|

Bell Rocket Belt

United States — experimental one-man back-pack flying system

Archive Photos

Bell No. 2 Rocket Belt at the National Air and Space Museum Steven F. Udvar-Hazy Center, Chantilly, Virginia (Photo by Jim Hough)

Overview

The Bell Rocket Belt is a low-power rocket propulsion device that allows an individual to safely travel or leap over small distances. It is a type of rocket pack.

In the early 1960s, Bell Aerosystems built a rocket pack which it called the "Bell Rocket Belt" or "man-rocket" for the US Army, using hydrogen peroxide as fuel. This concept was revived in the 1990s and today these packs can provide powerful, manageable thrust. This rocket belt’s propulsion works with superheated water vapor. A gas cylinder contains nitrogen gas, and two cylinders containing highly concentrated hydrogen peroxide. The nitrogen presses the hydrogen peroxide onto a catalyst, which decomposes the hydrogen peroxide into a mixture of superheated steam and oxygen with a temperature of about 740 °C. This was led by two insulated curved tubes to two nozzles where it blasted out, supplying the recoil. The pilot can vector the thrust by altering the direction of the nozzles through hand-operated controls. To protect from resulting burns the pilot had to wear insulating clothes.

One Bell Rocket Belt is on display at the Smithsonian Institution’s, National Air and Space Museum’s annex, the Steven F. Udvar-Hazy Center, located near Dulles Airport.

Use

The rocket could carry a man over 9-meter-high obstacles and reached a speed of 11 to 16 km/h. However, its flying time was limited to 20 seconds. A later advancement during the years 1995-2000 could not improve the flying time to any more than 30 seconds.

The rocket could carry a man over 9-meter-high obstacles and reached a speed of 11 to 16 km/h. However, its flying time was limited to 20 seconds. A later advancement during the years 1995-2000 could not improve the flying time to any more than 30 seconds.

Apart from the extremely limited working time, this rocket belt did not allow for a controlled landing should its drive fail, as it would operate at altitudes far too low for a parachute to function. This represents a substantial safety risk and differentiates the rocket belt from airplanes and helicopters, which can land safely without power by gliding or autorotation.

It has been used in presentations at Disneyland and at the 1984 Summer Olympics and 1996 Summer Olympics opening ceremonies. It has also been seen in movies and on television. This type of rocket belt was used in the James Bond film Thunderball of 1965. It also made an appearance in the Lost in Space television series.

Specifications - Bell Rocket Belt

General Characteristics

Performance

History

Wendell F. Moore began working on a rocket pack as early as 1953 (possibly, after learning about Thomas Moore’s work) while working as an engineer at Bell Aerosystems. Experiments began in the mid-1950s. Developing the engine did not present difficulties — the application of hydrogen peroxide was well developed by missilemen. The main problem was achieving stable and steady flight; for this, a reliable and convenient control system had to be developed.

In 1959 the U.S. Army contracted Aerojet General to conduct feasibility studies on a Rocket Belt and contracted Bell Aerosystems to develop a Small Rocket Lift Device (SRLD). The experimental rig, which worked on compressed nitrogen, was prepared. Its steel tubing frame allowed a tester to be attached to the rig. Two hinged nozzles were set on the frame. Nitrogen at 35 atmospheres (3.5 MPa) was supplied to the nozzles by flexible hoses. An engineer-operator on the ground regulated the supply of nitrogen through a valve. Additionally, the tester regulated the thrust using levers under his shoulders. The tester inclined the nozzles forward and backward, trying to reach stable hovering at a limited height. A safety tether was attached from below, so that the rig and tester could not fly too high.

Testing

The first tests showed that the human body was a very unstable platform. Experimental testing found the best arrangement for the jet nozzles relative to the center of gravity of both the pilot and pack. Experimentation allowed development of directional control for practical flight. Wendell Moore and other members of his group participated in the test flights. These first flights were more like short and sharp leaps, but further experiments proved the concept successful — in 1958 it was shown that the rig could reach stable flight at up to 5 meters for 3 minutes. The success of these experiments persuaded the military to proceed with development. The Bell company was awarded a contract to develop, flight test, and demonstration a practical SRLD.

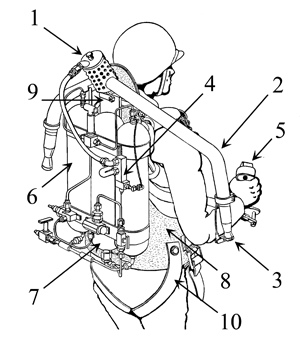

For the pack they selected a rocket engine with a thrust of 280 pounds-force (1.25 kN or 127 kgf). The pack with its fuel weighed 125 lb (57 kg). The pack had a solid glass-plastic frame contoured to the shape of the human body. The cylinders of fuel and nitrogen were attached to the frame. The Engine was fastened using a hinged assembly that was controlled by levers under the shoulders. The engine thrust was controlled through a regulator assembly connected to a throttle handle on the right lever of the device. The handle on the left lever governed the slant of the (jetavators) nozzles. The pilot was strapped to the frame and the tests of the pack began toward the end of 1960. Test flights were performed in a large hangar "on the leash" (i.e. with a safety tether). Wendell Moore completed the first 20 tethered takeoffs personally, checking the functioning of control systems, revealing deficiencies, and improving the construction of the device.

On 17 February 1961, the safety tether caused an accident. During the flight the pack veered sharply and carried the pilot and device to the left. It reached the limit of the tether, which broke. The pilot and heavy pack fell from approximately 2.5 meter height, breaking Moore’s kneecap. He could no longer fly. After this, Moore’s associate, engineer Harold Graham, accepted the role of test pilot. On 1 March flight testing was resumed. Graham carried out 36 more tethered tests. These test enabled him to master stable control of the pack. Finally, pilot and pack were ready for the next step. On 20 April 1961 (the week after Yuri Gagarin’s flight), on a vacant spot near the Niagara Falls airport, the first free flight in history of a rocket pack was performed. Harold Graham reached an altitude of approximately 4 feet (1.2 meters), and then flew smoothly forward at a speed of approximately 10 km/h. Pilot and pack flew 108 feet (less than 35 meters) and then landed. The entire flight lasted 13 seconds. It was at this moment that rocket packs ceased to be fantasy.

In subsequent flights Graham mastered the technology. He learned how to control the pack and perform more complex maneuvers: flying in a circle and turning on a spot. He flew over streams and cars, ten-meter hills, and between trees. From April through May 1961 Graham further perfected his techniques in 28 additional flights. Wendell Moore worked to attain absolute reliability from the pack and confident piloting from Graham in preparation of presenting the rocket pack to the public. In the course of testing maximums of duration and distance were achieved: duration 21 seconds; range 120 m; height 10 m; speed, 55 km/h.

Demonstrations

On 8 June 1962, the pack was publicly demonstrated for the first time before several hundred officers at the Fort Eustis military base. Other public demonstrations then followed, including the famous flight in the Pentagon courtyard. On that day Harold Graham flew before 3000 members of the military department, who observed with enthusiasm.

On 11 October 1961, (according to other data, 12 October) the pack was demonstrated personally to President John F. Kennedy in the course of exponential maneuvers on the military base Fort Bragg. Graham took off from an amphibious LST, flew over a strip of water, and landed in front of the President.

Harold Graham, along with an entire command of service personnel, traveled to many cities in the USA. They visited Canada, Mexico, Argentina, Germany, and France, as well as other countries. Each time they achieved enormous success demonstrating the rocket pack in action before the wide public. However, the army was disappointed. The maximum duration of flight of the rocket pack was 21 seconds, with a range of only 120 m. An entire command of service personnel needed to accompany the rocket pack. During flight 5 U.S. gallons (19 liters) of hydrogen peroxide was expended. In the opinion of the military, the "Bell Rocket Belt" was more a spectacular toy than an effective means of transport. The army spent $150,000 on the Bell Aerosystems contract. Bell spent an additional $50,000. The army refused any further expenditure on the SRLD program, and the contract was canceled.

Operating Principle

All existing rocket packs are based on the construction of the "Bell Rocket Belt" pack, developed in 1960-1969 by Wendell Moore. Moore’s pack has two major parts (see figure to the right):

All existing rocket packs are based on the construction of the "Bell Rocket Belt" pack, developed in 1960-1969 by Wendell Moore. Moore’s pack has two major parts (see figure to the right):

Operating Principle of Rocket Engine

Piloting

The pack has two levers, rigidly connected to the engine installation. Pressing on these levers, the pilot deflects the nozzles back, and the pack flies forward. Accordingly, raising this lever makes the pack move back. It is possible to lean the engine installation to the sides (because of the ball and socket joint) to fly sideways.

Control with the aid of the lever is somewhat rough; for finer control the pilot uses a handle on the left lever. This handle governs the tips of the jet nozzles. The tips (jetavators) are spring-opposed and can with the aid of the flexible thrusts be slanted forward or back. The pilot inclines the handle forward or back and slants both nozzle tips at the same time to fly straight. If pilot must turn, he turns handle, to slant the nozzles in opposite directions, one forward, another back, turning the pilot and the pack around its axis. By the combination of different motions of lever handles the pilot can fly any way, even sideways, to turn, rotate on the spot, etc.

The pilot can control his rocket pack’s flight differently, by changing the center of gravity of his body. For example, if we bend the legs and raise them to the stomach, the center of gravity will move forwards, and pack will be inclined and it will also fly forward. Such a control of pack, with the aid of the body, is considered incorrect and is characteristic of novices. Most experienced pilot Bill Suitor asserts that during the flight it is necessary to hold legs together and straight, and to control flight by the pack’s levers and handles. This is the only way to learn to competently pilot the pack and to confidently carry out complex aerial maneuvers.

On the right lever it is the "gas handle". In the fixed state it completely shuts the fuel regulator into the engine. Turning the handle counterclockwise, the pilot increases the engine thrust. During servicing of the pack with compressed nitrogen the handle is fixed in the closed position with a shear pin. The timer is on the same handle. Since the pack has fuel for only for 21 seconds of flight, it is necessary to know when the pack will run out of fuel, so that the pilot is not 10 meters above the ground when his tanks are empty.

Before the flight the timer is set for 21 second. When pilot turns the handle for the takeoff, the timer begins counting and will give second-by-second signals to a buzzer in the pilot’s helmet. In 15 seconds the signal becomes continuous, telling the pilot that it is time to land.

Special Features of Flights of the Bell Rocket Belt

The pack’s pilot wears shielding overalls made of thermal resistant material, since the exhaust jet and the engine’s pipes are very hot. The crash helmet (which has inside it the signal buzzer) is put on. The rocket thrust-chamber’s supersonic exhaust jet makes a deafeningly loud sound (by force to 130 decibels), more like a shrill screech than the roar of an aeroplane’s jet engine. The rocket pack is a very noisy flight vehicle.

As a rule, the jet exhaust is transparent and not visible in air. But in cold weather the water vapor, which is a large part of the steam-gas mixture, condenses soon after it leaves the nozzle, and then a cloud of water fog enwraps the pilot. Specifically, for this reason the very first tethered flights of the Bell Rocket Belt were carried out in a hangar — the reason was winter. The jet exhaust is also visible if the fuel is not decomposed completely in the gas generator, which occurs if the catalyst works poorly or the hydrogen peroxide is impure.

RB2000 Rocket Belt

In 1995, the construction of the rocket pack was improved. Three men from Texas, Bradley Wayne Barker (Brad Barker), Joe Wright, and Larry Stanley, after inviting professional inventor Doug Malewicki, built the new version of the rocket pack, which they named "RB 2000 Rocket Belt". The "RB 2000" pack in essence repeats the construction of Wendell Moore, but is made from light alloys (titanium, aluminum) and composite materials, has increased fuel stock and increased power. As a result its maximum duration of flight is increased to 30 seconds. On 12 June 1995 Bill Suitor flew the RB2000; afterwards he gave the RB2000 back to Bradley Wayne Barker, who drove away with it, and it has not been seen since. A lawsuit resulted. The story is recounted in the book The Rocketbelt Caper: A True Tale of Invention, Obsession and Murder by Paul Brown.

In 1992, one-time insurance salesman and entrepreneur Brad Barker formed a company to build a rocketbelt with two partners: Joe Wright, a businessman based in Houston, and Larry Stanley, an engineer who owned an oil well in Texas. By 1994, they had a working prototype they called the Rocketbelt-2000, or RB-2000. They even asked Bill] Suitor to fly it for them. But the partnership soon broke down. First Stanley accused Barker of defrauding the company. Then Barker attacked Stanley and went into hiding, taking the RB-2000 with him. Police investigators questioned Barker but released him after three days. The following year Stanley took Barker to court to recover lost earnings. The judge awarded Stanley sole ownership of the RB-2000 and over $10m in costs and damages. When Barker refused to pay up, Stanley kidnapped him, tied him up and held him captive in a box disguised as a SCUBA-tank container. After eight days Barker managed to escape. Police arrested Stanley and in 2002 he was sentenced to life in prison, since reduced to eight years. The rocketbelt has never been found.

| Technical Characteristics of Rocket Pack | ||

|---|---|---|

| Bell Rocket Belt | RB 2000 Rocket Belt | |

| Duration: | 21 seconds | 30 seconds |

| Thrust: | 136 kgf (1.33 kN) (calculated 127 kgf or 1.25 kN) | 145 kgf (1.42 kN) |

| Maximum distance: | Approximately 250 meters | |

| Maximum altitude: | 18 m | 30 m |

| Maximum speed: | 55 km/h | 96 km/h |

| Equipped mass: | 57 kg | 60 kg |

| Fuel stock: | 19 liters | 23 liters |

The Bell Rocket Belt was successful and popular but was limited in its potential uses to the Army due to limited fuel storage. As a result, the Army turned its attention to missile development, and the Rocket Belt project was discontinued.

References