| ||||

|---|---|---|---|---|

|

|

|

|

|

| ||||

|---|---|---|---|---|

|

|

|

|

|

Messerschmitt Bf.109F Friedrich

Single-engine Single-Seat High-Altitude Fighter Monoplane (Luftwaffe World War II Nazi Germany)

Archive Photos 1

1942 Messerschmitt Bf.109F-4 Friedrich (Luftwaffe 10132) World War II German Luftwaffe fighter on display (9/17/2003) at the Canada Aviation Museum, Ottawa, Ontario, Canada (Photos by John Shupek)

Messerschmitt Bf.109 Series Overview

The Messerschmitt Bf.109 is a German World War II fighter aircraft that was the backbone of the Luftwaffe’s fighter force. The Bf.109 first saw operational service in 1937 during the Spanish Civil War and was still in service at the dawn of the jet age at the end of World War II in 1945. It was one of the most advanced fighters of the era, including such features as all-metal monocoque construction, a closed canopy, and retractable landing gear. It was powered by a liquid-cooled, inverted-V12 aero engine. From the end of 1941, the Bf.109 was steadily being supplemented by the Focke-Wulf Focke-Wulf Fw.190.

It was commonly called the Me.109, most often by Allied aircrew and even among the German aces themselves, even though this was not the official German designation. The designation "Messerschmitt Bf.109" was issued by the Ministry of Aviation (German: Reichsluftfahrtministerium/RLM) and represents the firm that originally built them, the "Bavarian Aircraft Works", or Bayerische Flugzeugwerke (BFW) in German. The confusion arises because design work began in 1934 at the BFW firm and, as was customary, the model was designated by the prefix Bf. On 11 July 1938 the company was renamed Messerschmitt AG due to Willy Messerschmitt becoming its new owner, and the prefix Me was applied to all new models after that date, whilst existing types retained their Bf prefix.

It was designed by Willy Messerschmitt and Robert Lusser, who worked at Bayerische Flugzeugwerke during the early to mid-1930s.

Whilst the Bf.109 was conceived as an interceptor, later models were developed to fulfill multiple tasks, serving as bomber escort, fighter-bomber, day-, night-, all-weather fighter, ground-attack aircraft, and as reconnaissance aircraft. It was supplied to and operated by several states during World War II, and served with several countries for many years after the war. The Bf.109 is the most produced fighter aircraft in history, with a total of 33,984 airframes produced from 1936 up to April 1945.

The Bf.109 was flown by the three top-scoring German fighter aces of World War II, who claimed 928 victories among them while flying with Jagdgeschwader 52, mainly on the Eastern Front. The highest scoring fighter ace of all time, Erich Hartmann, flew the Bf.109 and was credited with 352 aerial victories. The aircraft was also flown by Hans-Joachim Marseille, the highest-scoring German ace in the North African Campaign, who achieved 158 aerial victories. It was also flown by several other aces from Germany’s allies, notably Finn Ilmari Juutilainen, the highest scoring non-German ace on the type, and pilots from Italy, Romania, Croatia, Bulgaria and Hungary. Through constant development, the Bf.109 remained competitive with the latest Allied fighter aircraft until the end of the war.

Design and Development

Origins

During 1933, the Technisches Amt (C-Amt), the technical department of the Reichsluftfahrtministerium (RLM) ("Reich Aviation Ministry"), concluded a series of research projects into the future of air combat. The result of the studies was four broad outlines for future aircraft:

Rüstungsflugzeug III was intended to be a short range interceptor, replacing the Arado Ar.64 and Heinkel He.51 biplanes then in service. In late March 1933 the RLM published the tactical requirements for a single-seat fighter in the document L.A. 1432/33.

The fighter needed to have a top speed of 400 km/h (250 mph) at 6,000 m (19,690 ft), to be maintained for 20 minutes, while having a total flight duration of 90 minutes. The critical altitude of 6,000 metres was to be reached in no more than 17 minutes, and the fighter was to have an operational ceiling of 10,000 metres. Power was to be provided by the new Junkers Jumo 210 engine of about 522 kW (700 hp). It was to be armed with either a single 20mm MG C/30 engine-mounted cannon firing through the propeller hub as a Motorkanone, or two synchronized, engine cowl-mounted 7.92 mm (.312 in) MG 17 machine guns, or one lightweight engine-mounted 20mm MG FF cannon with two 7.92 mm MG 17s.[9] The MG C/30 was an airborne adaptation of the 2 cm FlaK 30 anti-aircraft gun, which fired very powerful "Long Solothurn" ammunition, but was very heavy and had a low rate of fire. It was also specified that the wing loading should be kept below 100 kg/m². The performance was to be evaluated based on the fighter’s level speed, rate of climb, and maneuverability, in that order.

It has been suggested that Bayerische Flugzeugwerke (BFW) was originally not invited to participate in the competition due to personal animosity between Willy Messerschmitt and RLM director Erhard Milch; however, recent research by Willy Radinger and Walter Shick indicates that this may not have been the case, as all three competing companies’Arado, Heinkel and BFW’received the development contract for the L.A. 1432/33 requirements at the same time in February 1934. A fourth company, Focke-Wulf, received a copy of the development contract only in September 1934. The powerplant was to be the new Junkers Jumo 210, but the proviso was made that it would be interchangeable with the more powerful, but less developed Daimler-Benz DB.600 powerplant. Each was asked to deliver three prototypes for head-to-head testing in late 1934.

Prototypes

Design work on Messerschmitt Project Number P.1034 began in March 1934, just three weeks after the development contract was awarded. The basic mock-up was completed by May, and a more detailed design mock-up was ready by January 1935. The RLM designated the design as type "Bf.109," the next available from a block of numbers assigned to BFW.

The first prototype (Versuchsflugzeug 1 or V1), with civilian registration D-IABI, was completed by May 1935, but the new German engines were not yet ready. To get the "R III" designs into the air, the RLM acquired four Rolls-Royce Kestrel VI engines by trading Rolls-Royce a Heinkel He.70 Blitz for use as an engine test-bed. Messerschmitt received two of these engines and adapted the engine mounts of V1 to take the V-12 engine upright. V1 made its maiden flight at the end of May 1935 at the airfield located in the southernmost Augsburg neighborhood of Haunstetten, piloted by Hans-Dietrich "Bubi" Knoetzsch. After four months of flight testing, the aircraft was delivered in September to the Luftwaffe’s central test center at the Erprobungsstelle Rechlin to take part in the design competition.

In 1935, the first Jumo engines became available, so V2 was completed in October using the 449 kW (600 hp) Jumo 210A engine. V3 followed, the first to be mounted with guns, but it did not fly until May 1936 due to a delay in procuring another Jumo 210 engine.

Design Competition

After Luftwaffe acceptance trials were completed at their headquarters Erprobungsstelle (E-Stelle) military aviation test and development facility at Rechlin, the prototypes were moved to the subordinate E-Stelle Baltic seacoast facility at Travemünde for the head-to-head portion of the competition. The aircraft participating in the trials were the Arado Ar.80-V3, the Focke-Wulf Fw.159-V3, the Heinkel He.112-V4 and the Bf.109-V2. The He.112 arrived first, in early February 1936, followed by the rest of the prototypes by the end of the month.

Because most fighter pilots of the Luftwaffe were used to biplanes with open cockpits, low wing loading, light g-forces and easy handling like the Heinkel He.51, they were very critical of the Bf.109 at first. However, it soon became one of the front-runners in the contest, as the Arado and Focke-Wulf entries, which were intended as "backup" programs to safeguard against failure of the two favorites, proved to be completely outclassed. The Arado Ar.80, with its gull wing (replaced with a straight, tapered wing on the V3) and fixed, spatted undercarriage was overweight and underpowered, and the design was abandoned after three prototypes had been built. The parasol winged Fw.159, potentially inspired by the same firm’s earlier Focke-Wulf Fw.56, was always considered by the E-Stelle Travemünde facility’s staff to be a compromise between a biplane and an aerodynamically more efficient, low-wing monoplane. Although it had some advanced features, it used a novel, complex retractable main undercarriage which proved to be unreliable.

Initially, the Bf.109 was regarded with disfavor by E-Stelle test pilots because of its steep ground angle, which resulted in poor forward visibility when taxiing; the sideways-hinged cockpit canopy, which could not be opened in flight; and the automatic leading edge slats on the wings which, it was thought, would inadvertently open during aerobatics, possibly leading to crashes. This was later borne out in combat situations and aerobatic testing by various countries’ test establishments. The leading edge slats and ailerons would flutter rapidly in fast tight turns, making targeting and control difficult, and eventually putting the aircraft into a stall condition. They were also concerned about the high wing loading.

The Heinkel He.112, based on a scaled-down Blitz, was the favorite of the Luftwaffe leaders. Compared with the Bf.109, it was also cheaper. Positive aspects of the He.112 included the wide track and robustness of the undercarriage (this opened outwards from mid wing, as opposed to the Bf.109s which opened from the wing root), considerably better visibility from the cockpit, and a lower wing loading that made for easier landings. In addition, the V4 had a single-piece, clear-view, sliding cockpit canopy and a more powerful Jumo 210Da engine with a modified exhaust system. However, the He.112 was also structurally complicated, being 18% heavier than the Bf.109, and it soon became clear that the thick wing, which spanned 12.6 m (41 ft 4 in) with an area of 23.2 m² (249.7 ft²) on the first prototype (V1), was a disadvantage for a light fighter, decreasing the aircraft’s rate of roll and maneuverability. As a result, the He.112-V4 which was used for the trials had new wings, spanning 11.5 m (37 ft 8.75 in) with an area of 21.6 m² (232.5 ft²). However, the improvements had not been fully tested and the He.112-V4 could not be demonstrated in accordance with the rules laid down by the Acceptance Commission, placing it at a distinct disadvantage.

Because of its smaller, lighter airframe, the Bf.109 was 30 km/h (20 mph) faster than the He.112 in level flight, and superior in climbing and diving. The Commission ultimately ruled in favor of the Bf.109 because of the Messerschmitt test pilot’s demonstration of the Bf.109’s capabilities during a series of spins, dives, flick rolls and tight turns, throughout which the pilot was in complete control of the aircraft.

In March, the RLM received news that the British Supermarine Spitfire had been ordered into production. It was felt that a quick decision was needed to get the winning design into production as soon as possible, so on 12 March, the RLM announced the results of the competition in a document entitled Bf.109 Priority Procurement, which ordered the Bf.109 into production. At the same time, Heinkel was instructed to radically redesign the He.112. The Messerschmitt Bf.109 made its public debut during the 1936 Berlin Olympics, when the V1 prototype was flown.

Design Features

As with the earlier Bf.108, the new design was based on Messerschmitt’s "lightweight construction" principle, which aimed to minimize the number of separate parts in the aircraft. Examples of this could be found in the use of two large, complex brackets which were fitted to the firewall. These brackets incorporated the lower engine mounts and landing gear pivot point into one unit. A large forging attached to the firewall housed the main spar pick-up points, and carried most of the wing loads. Contemporary design practice was usually to have these main load-bearing structures mounted on different parts of the airframe, with the loads being distributed through the structure via a series of strong-points. By concentrating the loads in the firewall, the structure of the Bf.109 could be made relatively light and uncomplicated.

An advantage of this design was that the main landing gear, which retracted through an 85-degree angle, was attached to the fuselage, making it possible to completely remove the wings for servicing without additional equipment to support the fuselage. It also allowed simplification of the wing structure, since it did not have to bear the loads imposed during takeoff or landing. The one major drawback of this landing gear arrangement was its narrow wheel track, making the aircraft unstable while on the ground. To increase stability, the legs were splayed outward somewhat, creating another problem in that the loads imposed during takeoff and landing were transferred up through the legs at an angle.

The small rudder of the Bf.109 was relatively ineffective at controlling the strong swing created by the powerful slipstream of the propeller during the early portion of the takeoff roll, and this sideways drift created disproportionate loads on the wheel opposite to the swing. If the forces imposed were large enough, the pivot point broke and the landing gear leg would collapse outward into its bay. Experienced pilots reported that the swing was easy to control, but some of the less-experienced pilots lost fighters on takeoff.

Because of the large ground angle caused by the long legs, forward visibility while on the ground was very poor, a problem exacerbated by the sideways-opening canopy. This meant that pilots had to taxi in a sinuous fashion which also imposed stresses on the splayed undercarriage legs. Ground accidents were a problem with rookie pilots, especially during the later stages of the war when pilots received less training before being sent to operational units. At least 10% of all Bf.109s were lost in takeoff and landing accidents, 1,500 of which occurred between 1939 and 1941. The installation of a fixed "tall" tailwheel on some of the late G-10s and 14s and the K-series helped alleviate the problem to a large extent.

From the inception of the design, priority was given to easy access to the powerplant, fuselage weapons and other systems while the aircraft was operating from forward airfields. To this end, the entire engine cowling was made up of large, easily removable panels which were secured by large toggle latches. A large panel under the wing center section could be removed to gain access to the L-shaped main fuel tank, which was sited partly under the cockpit floor and partly behind the rear cockpit bulkhead. Other, smaller panels gave easy access to the cooling system and electrical equipment. The engine was held in two large, forged, Elektron magnesium alloy Y-shaped legs, one per side straddling the engine block, which were cantilevered from the firewall. Each of the legs was secured by two quick-release screw fittings on the firewall. All of the main pipe connections were color-coded and grouped in one place, where possible, and electrical equipment plugged into junction boxes mounted on the firewall. The entire powerplant could be removed or replaced as a unit in a matter of minutes, a potential step to the eventual adoption of the unitized-powerplant Kraftei engine mounting concept used by many German combat aircraft designs, later in the war years.

Another example of the Bf.109’s advanced design was the use of a single, I-beam main spar in the wing, positioned more aft than usual (to give enough room for the retracted wheel), thus forming a stiff D-shaped torsion box. Most aircraft of the era used two spars, near the front and rear edges of the wings, but the D-box was much stiffer torsionally, and eliminated the need for the rear spar. The wing profile was the NACA 2R1 14.2 at the root and NACA 2R1 11.35 at the tip, with a thickness to chord ratio of 14.2% at the root and 11.35% at the tip.

Another major difference from competing designs was the higher wing-loading. While the R-IV contract called for a wing-loading of less than 100 kg/m², Messerschmitt felt this was unreasonable. With a low wing-loading and the engines available, a fighter would end up being slower than the bombers it was tasked with catching.

A fighter was designed primarily for high-speed flight. A smaller wing area was optimal for achieving high speed, but low-speed flight would suffer, as the smaller wing would require more airflow to generate enough lift to maintain flight. To compensate for this, the Bf.109 included advanced high-lift devices on the wings, including automatically-opening leading edge slats, and fairly large camber-changing flaps on the trailing edge. The slats increased the lift of the wing considerably when deployed, greatly improving the horizontal maneuverability of the aircraft, as several Luftwaffe veterans, such as Erwin Leykauf, attest. Messerschmitt also included ailerons that "drooped" when the flaps were lowered (F series and later the lower radiator flap operated as part of the flap system), thereby increasing the effective flap area . When deployed, these devices effectively increased the wings’ coefficient of lift.

Fighters with liquid-cooled engines were vulnerable to hits in the cooling system. For this reason, on later Bf.109 F, G and K models the two coolant radiators were equipped with a cut-off system. If one radiator leaked, it was possible to fly on the second, or to fly for at least five minutes with both closed. In 1943, Oberfeldwebel Edmund Roßmann got lost and landed behind Soviet lines. He agreed to show the Soviets how to service the plane. Soviet machine gun technician Viktor M. Sinaisky recalled:

The Messer was a very well designed plane. First, it had an engine of an inverted type, so it could not be knocked out from below. It also had two water radiators with a cut-off system: if one radiator leaked you could fly on the second or close both down and fly at least five minutes more. The pilot was protected by armor-plate from the back, and the fuel tank was also behind armor. Our planes had fuel tanks in the center of their wings: that’s why our pilot got burnt. What else did I like about the Messer? It was highly automatic and thus easy to fly. It also employed an electrical pitch regulator, which our planes didn’t have. Our propeller system, with variable pitch was hydraulic, making it impossible to change pitch without engine running. If, God forbid, you turned off the engine at high pitch, it was impossible to turn the propeller and was very hard to start the engine again. Finally, the German ammo counter was also a great thing.

Armament and Gondola Cannons

Reflecting Messerschmitt’s belief in low-weight, low-drag, simple monoplanes, the armament was placed in the fuselage. This kept the wings very thin and light. Two synchronized machine guns were mounted in the cowling, firing over the top of the engine and through the propeller arc. An alternative arrangement was also designed, consisting of a single auto-cannon firing through a blast tube between the cylinder banks of the engine, known as a Motorkanone mount in German. This was also the choice of armament layout on some contemporary monoplane fighters, such as the French Dewoitine D.520, or the American Bell P-39 Airacobra, and dated back to World War I’s small run of SPAD S.XII moteur-canon, 37 mm cannon-armed fighters in France.

When it was discovered in 1937 that the RAF was planning eight-gun batteries for its new Hawker Hurricane and Supermarine Spitfire fighters, it was decided that the Bf.109 should be more heavily armed. The problem was that the only place available to mount additional guns was in the wings. Only one spot was available in each wing, between the wheel well and slats, with room for only one gun, either a 7.92 mm MG 17 machine gun, or a 20mm MG FF or MG FF/M cannon.

The first version of the Bf.109 to have wing guns was the C-1, which had one MG 17 in each wing. To avoid redesigning the wing to accommodate large ammunition boxes and access hatches, an unusual ammunition feed was devised whereby a continuous belt holding 500 rounds was fed along chutes out to the wing tip, around a roller and then back along the wing, forward and beneath the gun breech, to the wing root, where it coursed around another roller and back to the weapon.

The gun barrel was placed in a long, large-diameter tube located between the spar and the leading edge. The tube channeled cooling air around the barrel and breech, exhausting out of a slot at the rear of the wing. The installation was so cramped that parts of the MG 17’s breech mechanism extended into an opening created in the flap structure.

The much longer and heavier MG FF had to be mounted farther along the wing in an outer bay. A large hole was cut through the spar allowing the cannon to be fitted with the ammunition feed forward of the spar, while the breech block projected rearward through the spar. A 60-round ammunition drum was placed in a space closer to the wing root causing a bulge in the underside. A small hatch was incorporated in the bulge to allow access for changing the drum. The entire weapon could be removed for servicing by removing a leading edge panel.

From the Bf.109F-series onwards, guns were no longer carried inside the wings. Instead, the Bf.109F had a 20mm gun firing through the propeller shaft. The change was disliked by leading fighter pilots such as Adolf Galland and Walter Oesau, but others such as Werner Mölders considered the single nose-mounted gun to compensate well for the loss of the two wing guns. Galland had his Bf.109F-2 field-modified with a 20mm MG FF/M auto-cannon, the "/M" suffix indicating the capability of firing thin-walled 20mm Minengeschoss shells, installed internally in each wing.

In place of internal wing armament, additional firepower was provided through a pair of 20mm MG 151/20 cannons installed in conformal gun pods under the wings. The conformal gun pods, exclusive of ammunition, weighed 135 kg (298 lb); and 135 to 145 rounds were provided per gun. The total weight, including ammunition, was 215 kg. Installation of the under-wing gun pods was a simple task that could be quickly performed by the unit’s armorers, and the gun pods imposed a reduction of speed of only 8 km/h (5 mph). By comparison, the installed weight of a similar armament of two 20mm MG 151/20 cannon inside the wings of the Fw.190A-4/U8 was 130 kg (287 lb), without ammunition.

Although the additional armament increased the fighter’s potency as a bomber destroyer, it had an adverse effect on the handling qualities, reducing its performance in fighter-versus-fighter combat and accentuating the tendency of the fighter to swing pendulum-fashion in flight.

Some of the projected Bf.109K-series models, such as the K-6, were designed to carry 30 mm (1.18 in) MK 108 cannons in the wings.

Designation and Nicknames

Originally the aircraft was designated as Bf.109 by the RLM, since the design was submitted by the Bayerische Flugzeugwerke (literally "Bavarian Aircraft Works", meaning "Bavarian Aircraft Factory"; sometimes abbreviated B.F.W., akin to BMW) during 1935. The company was renamed Messerschmitt AG after 11 July 1938 when Erhard Milch finally allowed Willy Messerschmitt to acquire the company. All Messerschmitt aircraft that originated after that date, such as the Me.210, were to carry the "Me" designation. Despite regulations by the RLM, wartime documents from Messerschmitt AG, RLM and Luftwaffe loss and strength reports continued to use both designations, sometimes even on the same page.

All extant airframes bear the official "Bf.109" designation on their identification plates, including the final K-4 models. The aircraft was often referred to by the folk-designation, ’Me.109’, particularly by the Allies.

The aircraft was often nicknamed Messer by its operators and opponents alike; the name was not only an abbreviation of the manufacturer, but also the German word for "knife". In Finland, the Bf.109 was known as Mersu, although this was originally the Finnish nickname for Mercedes-Benz cars.

Soviet aviators nicknamed the Bf.109 "the skinny one" (khudoy), for its sleek appearance compared, for example, to the more robust Fw.190.

The names "Anton", "Berta", "Caesar", "Dora", "Emil", "Friedrich", "Gustav", and "Kurfürst" were derived from the variant’s official letter designation (e.g. Bf.109G - "Gustav"), based on the German spelling alphabet of World War II, a practice that was also used for other German aircraft designs. The G-6 variant was nicknamed by Luftwaffe personnel as Die Beule ("the bump/bulge") because of the cowling’s characteristic, bulging covers for the breeches of the 13 mm (.51 in) MG 131 machine guns, with the separate Beule covers eliminated by the time of the G-10 model’s introduction of a subtly reshaped upper cowling.

Record-setting Flights

In July 1937, not long after the public debut of the new fighter, three Bf.109Bs took part in the Flugmeeting airshow in Zürich under the command of Major Seidemann. They won in several categories: First prize in a speed race over a 202 km course, first prize in the class A category in the international Alpenrundflug for military aircraft, and victory in the international Patrouillenflug category. On 11 November 1937, the Bf.109-V13, D-IPKY flown by Messerschmitt’s chief pilot Dr. Hermann Wurster, powered by a 1,230 kW (1,650 hp) DB.601R racing engine, set a new world air speed record for landplanes with piston engines of 610.95 km/h (379.62 mph), winning the title for Germany for the first time. Converted from a Bf.109D, the V13 had been fitted with a special racing DB.601R engine that could deliver 1,230 kW (1,650 hp) for short periods.

Heinkel, having had the He.112 rejected in the design competition of 1936, designed and built the He.100. On 6 June 1938, the He.100-V3, flown by Ernst Udet, captured the record with a speed of 634.7 km/h (394.4 mph). On 30 March 1939, test pilot Hans Dieterle surpassed that record, reaching 746.61 km/h (463.92 mph) with the He.100-V8. Messerschmitt, however, soon regained the lead when, on 26 April 1939, Flugkapitän Fritz Wendel, flying the Me.209-V1, set a new record of 755.14 km/h (469.22 mph). For propaganda purposes, the machine was called the Me.109R, suggesting it was just another variant of the standard fighter, but in fact it was a racing aircraft having little in common with the Bf.109. It was powered by the DB.601ARJ, producing 1,156 kW (1,550 hp), but capable of reaching 1,715 kW (2,300 hp). This world record for a piston-engined aircraft was to stand until 1969, when Darryl Greenamyer’s modified Grumman F8F Bearcat, Conquest I, broke it with a 777 km/h (483 mph) record speed.

Variants

When the Bf.109 was designed in 1934, by a team led by Willy Messerschmitt and Robert Lusser, its primary role was that of a high-speed, short range interceptor. It used the most advanced aerodynamics of the time and embodied advanced structural design which was ahead of its contemporaries. In the early years of the war, the Bf.109 was the only single-engined fighter operated by the Luftwaffe, until the appearance of the Focke-Wulf Fw.190.

The Bf.109 remained in production from 1937 through 1945 in many different variants and sub-variants. The primary engines used were the Daimler-Benz DB.601 and DB.605, though the Junkers Jumo 210 powered most of the pre-war variants. The most-produced Bf.109 model was the Bf.109G series (more than a third of all Bf.109s built were the G-6 series, 12,000 units being manufactured from March 1943 until the end of the war).

The initial production models of the A, B, C and D series were powered by the relatively low-powered, 670-700 PS (660-690 HP) Junkers Jumo 210 series engines. A few prototypes of these early aircraft were converted to use the more powerful DB.600.

The first major redesign came with the E series, including the naval variant, the Bf.109T (T standing for Träger, or carrier). The Bf.109E, or "Emil", introduced structural changes to accommodate the heavier, but significantly more powerful 1,100 PS (1,085 HP) Daimler-Benz DB.601 engine, heavier armament, and increased fuel capacity. Partly due to its limited 300 km (186 mile) combat radius on internal fuel alone, resulting from its 660 km (410 mile) range limit, later variants of the Es introduced a fuselage ordnance rack for fighter-bomber duty, or provision for a long-range, standardized 300 liter (79 US gallon) drop-tank, and used the DB.601N engine of higher power output. The Bf.109E first saw service with the "Condor Legion" during the last phase of the Spanish Civil War and was the main variant from the beginning of World War II until mid-1941 when the Bf.109F replaced it in the pure fighter role. (Eight Bf.109Es were assembled in Switzerland in 1946 by the Dornier-Werke, using licence built airframes; a ninth airframe was assembled using spare parts.)

The second major redesign during 1939-40 gave birth to the F series. The "Friedrich" had a complete redesign of the wings, the cooling system, and fuselage aerodynamics, and was powered by the 1,175 PS (1,159 HP) DB.601N (F-1, F-2) or the 1,350 PS (1,332 HP) DB.601E (F-3, F-4). Considered by many as the high-water mark of Bf.109 development, the F series abandoned the wing cannon and concentrated all armament in the forward fuselage with a pair of synchronized machine guns above and a single 15 or 20mm Motorkanone-mount cannon behind the engine, the latter firing between the cylinder banks and through the propeller hub, itself covered by a more streamlined, half-elliptical shaped spinner that better matched the streamlining of the reshaped cowling, abandoning the smaller, conical spinner of the Emil subtype. The F-type also omitted the earlier stabilizer lift strut on either side of the tail. The F-subtype’s improved aerodynamic configuration was used by all subsequent variants. Some Bf.109Fs were used late in the Battle of Britain in 1940, but the variant came into common use only in the first half of 1941.

The G series, or "Gustav", was introduced in mid-1942. Its initial variants (G-1 through G-4) differed only in minor details from the Bf.109F, most notably in the more powerful 1475 PS (1,455 HP) DB.605 engine. Odd-numbered variants were built as high-altitude fighters with a pressurized cockpit and GM-1 boost, while even-numbered variants were not pressurized, air superiority fighters, and fighter-bombers. Long-range photo-reconnaissance variants also existed. The later G series (G-5 through G-14) was produced in a multitude of variants, with uprated armament and provision for kits of packaged, generally factory-installed parts known as Umrüst-Bausätze (usually contracted to Umbau) and adding a "/U" suffix to the aircraft designation when installed. Field kits known as Rüstsätze were also available for the G-series, but those did not change the aircraft designation. By early 1944, tactical requirements resulted in the addition of MW-50 water injection boost and high-performance superchargers, boosting engine output to 1,800-2,000 PS (1,775-1,973 HP). From early 1944, some G-2s, G-3s, G-4s, and G-6s were converted to two-seat trainers, known as G-12s. An instructor’s cockpit was added behind the original cockpit and both were covered by an elongated, glazed canopy.

The final production version of the Bf.109 was the K series, or "Kurfürst", introduced in late 1944, powered by the DB.605D engine with up to 2,000 PS (1,973 HP). Though externally akin to the late production Bf.109G series, a large number of internal changes and aerodynamic improvements was incorporated that improved its effectiveness and remedied existing flaws, keeping it competitive with the latest Allied and Soviet fighters. The Bf.109’s outstanding rate of climb was superior to many Allied adversaries including the P-51D Mustang, Spitfire Mk. XIV, and Hawker Tempest Mk. V.

After the war, the Bf.109 was built in Czechoslovakia, as the Avia S-99 and S-199, and in Spain as the Hispano Aviación Ha 1109 and 1112.

Production

Total Bf.109 production was 33,984 units; Wartime production (September 1939 to May 1945) was 30,573 units. Fighter production totalled 47% of all German aircraft production, and the Bf.109 accounted for 57% of all German fighter types produced. A total of 2,193 Bf.109 A-E was built prewar, from 1936 to August 1939.

Some 865 Bf.109G derivatives were manufactured postwar under licence as Czechoslovak-built Avia S-99 and S-199s, with the production ending in 1948. Production of the Spanish-built Hispano Aviación HA-1109 and HA-1112 Buchons ended in 1958.

Operational History

The first Bf.109As served in the Spanish Civil War. By September 1939, the Bf.109 had become the main fighter of the Luftwaffe, replacing the biplane fighters, and was instrumental in gaining air superiority for the Wehrmacht during the early stages of the war. During the Battle of Britain, it was pressed into the role of escort fighter, a role for which it was not originally designed, and it was widely employed as a fighter-bomber, as well as a photo-reconnaissance platform. Despite mixed results over Britain, with the introduction of the improved Bf.109F in early 1941, the type again proved to be an effective fighter during the Invasion of Yugoslavia (where it was used by both sides), the Battle of Crete, Operation Barbarossa, the invasion of the USSR, and the Siege of Malta.

In 1942, it began to be partially replaced in Western Europe by a new German fighter, the Focke-Wulf Fw.190, but it continued to serve in a multitude of roles on the Eastern Front and in the Defense of the Reich, as well as in the Mediterranean Theatre of Operations and with Erwin Rommel’s Afrikakorps. It was also supplied to several of Germany’s allies, including Finland, Hungary, Romania, Bulgaria, Croatia, and Slovakia.

More aerial kills were made with the Bf.109 than any other aircraft of World War II. Many of the aerial victories were accomplished against poorly trained and badly organized Soviet forces in 1941 during Operation Barbarossa. The Soviets lost 21,200 aircraft at this time, about half to combat. If shot down, the Luftwaffe pilots might land or parachute to friendly territory and return to fight again. Later in the war, when Allied victories began to bring the fight closer, and then to German territory, bombing raids supplied plenty of targets for the Luftwaffe. This unique combination of events ’ until a major change in American fighter tactics occurred very early in 1944, that steadily gave the USAAF daylight air supremacy over the Reich ’ led to the highest-ever individual pilot victory scores. One hundred and five Bf.109 pilots were each credited with the destruction of 100 or more enemy aircraft. Thirteen of these men scored more than 200 kills, while two scored more than 300. Altogether, this group of pilots was credited with a total of nearly 15,000 kills. Though no official "ace" status existed in the Luftwaffe (unofficially, the term Experte (expert) was used for an experienced pilot irrespective of his number of kills), using the Allied definition of pilots who scored five or more kills, more than 2,500 Luftwaffe fighter pilots were considered aces in World War II. Against the Soviets, Finnish-flown Bf.109Gs claimed a victory ratio of 25:1. Bf.109s remained in foreign service for many years after World War II. The Swiss used their Bf.109Gs well into the 1950s. The Finnish Air Force did not retire their Bf.109Gs until March 1954. Romania used its Bf.109s until 1955. The Spanish Hispanos flew even longer. Some were still in service in the late 1960s. They appeared in films (notably Battle of Britain) playing the role of Bf.109Es. Some Hispano airframes were sold to museums, which rebuilt them as Bf.109s.

Operators

Note, this list includes operators who used Bf.109s for active service or combat. It does not include the United States, the United Kingdom and the Soviet Union, which all operated small numbers of captured aircraft for testing and evaluation,

Specifications Messerschmitt Bf.109F Friedrich [3, 4]

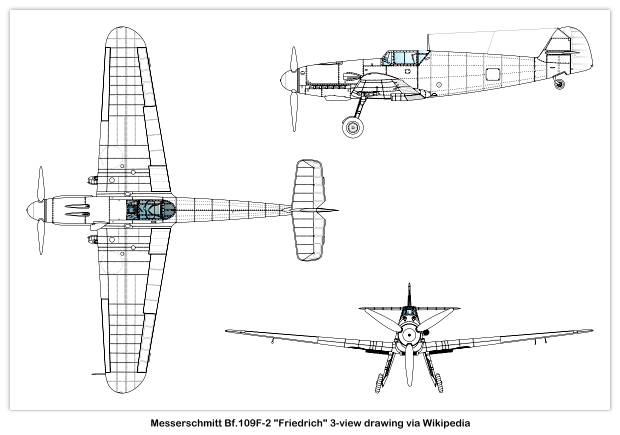

The latest development of the Messerschmitt Bf.109 is the Messerschmitt Bf.109F Friedrich. This aircraft incorporates several new features over the Bf.109E which are intended to increase performance at height, maneuverability and fire-power. The most obvious external modifications are the rounded wing-tips, the symmetrical nose, with large spinner and the cantilever tail-plane.

Increased performance has been gained by the installation of a Mercedes-Benz DB.601N engine developing 1,150 h.p. at 2,600 rpm for take-off and rated at 1,050 hp at 16,500 ft (5,030 m). A higher compression ratio is estimated to give an increase in power of about 6% at all heights over the earlier DB.601IA. This results in an estimated increase of 2%·in top speed at rated height and raises the top speed from 354 mph (566.4 km/h) to 362 mph (579.2 km/h) at 13,300 ft (4,060 m). At 21,000 ft (6,410 m) the top speed is 371 mph (594 km/h). The ceiling is 37,000 ft (11,285 m).

The armament now consists of one Mauser cannon housed in the inverted Vee of the engine and firing through the airscrew hub and two Rheinmetal-Borsig machine-guns in the fuselage top decking. The Bf.109F-1 series has a 20mm cannon and the BF.109F-2 series incorporates a 15 mm cannon. The Mauser cannon is said to have a rate of fire of 900 rounds per minute.

In the following description, those features which differ from the Bf.109E noted with an *. The general structure of the Bf.109E and the Bf.109F are generally the same.

Type:*

Wings:*

Fuselage:*

Tail Unit:*

Undercarriage:*

Power Plant:*

Accommodation:*

Armament:*

Dimensions:*

Weights and Loadings:*

Performance:*

References

Skytamer.com, Est. 1998